Difference between revisions of "Hardware:GPA"

| Line 17: | Line 17: | ||

[https://tabletop.martinos.org/images/b/b9/MIT-GPA-v3-fixed.zip Click here] to download Eagle version 6 board (.brd) and schematic (.sch) files for the V3 GPA board (does not include on-board DAC). | [https://tabletop.martinos.org/images/b/b9/MIT-GPA-v3-fixed.zip Click here] to download Eagle version 6 board (.brd) and schematic (.sch) files for the V3 GPA board (does not include on-board DAC). | ||

| + | |||

| + | [Mit_gpa_schematic_V3.png|Version 1 Gradient Power Amplifier circuit providing a single channel of output current] | ||

<gallery caption="Gradient Power Amplifier enclosure" widths="350px" heights="250px" perrow="2"> | <gallery caption="Gradient Power Amplifier enclosure" widths="350px" heights="250px" perrow="2"> | ||

| − | |||

image:Photo.JPG|GPA boards mounted in enclosure with power supplies, terminal blocks, and digital-to-analog converter boards. The boards were run on bipolar +15V and -15V rails provided by CUI switching supplies. On-board regulators provide +12V, -12V, and +5V for powering the small ICs. The +12V fan is powered by a small JST connector on the CUI supplies. | image:Photo.JPG|GPA boards mounted in enclosure with power supplies, terminal blocks, and digital-to-analog converter boards. The boards were run on bipolar +15V and -15V rails provided by CUI switching supplies. On-board regulators provide +12V, -12V, and +5V for powering the small ICs. The +12V fan is powered by a small JST connector on the CUI supplies. | ||

image:Front panel photo.JPG|Aluminum front panels were made using a water-jet cutter. [http://www.mouser.com/ProductDetail/Bud-Industries/NHC-14157/?qs=W%252bB5Pl59bv4hUDQy1Kr8cw== Hammond NHC-14157 enclosures] were used to house the GPAs and DACs. [https://gate.nmr.mgh.harvard.edu/wiki/Tabletop_MRI/images/8/89/2013_07_10_Panel_Dimensions_V3_WORKS_ON_OMAX_SOFTWARE_USING_AUTOCAD_2004_FORMAT.dxf.zip Click here for DXF file for front panel cut-outs]. Note that Version 2 of the GPA board requires a horizontal slot for the RJ45 connectors instead of the vertical slot used here. | image:Front panel photo.JPG|Aluminum front panels were made using a water-jet cutter. [http://www.mouser.com/ProductDetail/Bud-Industries/NHC-14157/?qs=W%252bB5Pl59bv4hUDQy1Kr8cw== Hammond NHC-14157 enclosures] were used to house the GPAs and DACs. [https://gate.nmr.mgh.harvard.edu/wiki/Tabletop_MRI/images/8/89/2013_07_10_Panel_Dimensions_V3_WORKS_ON_OMAX_SOFTWARE_USING_AUTOCAD_2004_FORMAT.dxf.zip Click here for DXF file for front panel cut-outs]. Note that Version 2 of the GPA board requires a horizontal slot for the RJ45 connectors instead of the vertical slot used here. | ||

Revision as of 19:16, 6 August 2016

Gradient Power Amplifier

The gradient amplifier is used to supply the current to the gradient coils. Since it's the fields we care about, and the fields are proportional to current, this amplifier can be viewed as a voltage to current transducer; it takes a voltage waveform from the console and creates a current proportional to that voltage in the gradient coil. It is similar to a common audio power amplifier except that it must also be able to output DC currents. It uses two OPA 549 power op-amps in a bridged configuration. A current sensor compares the output current to the input voltage to ensure that the current itself is proportional to the desired signal. The current sensor consists of an INA105 differential amplifier that measures the voltage across a small (0.1 ohm) resistor in series with the output. The OPA549s can provide up to 8 amps of current, but in practice the current is limited by the duty cycle of the gradient waveform in the pulse sequence and the size of the heat sink used on the boards.

Two versions of the board have been used with the tabletop scanner. Version 1 used separate digital-to-analog converter (DAC) boards and provided one output channel per GPA board. Version 2 simplified the wiring and reduced costs by placing three channels with integrated DAC stages onto a single PCB. Version 2 is plug-and-play compatible with the MEDUSA console digital gradient waveform output lines (RJ45 connector).

Email jaystock@nmr.mgh.harvard.edu with any questions.

Version 1 of the GPA board

Click here to view the schematic for the GPA boards generated in Eagle (version 6). Note that a separate A/D converter was used in the initial realization of the boards (DAC on the GPAs was not populated).

Click here to download Eagle version 6 board (.brd) and schematic (.sch) files for the V3 GPA board (does not include on-board DAC).

[Mit_gpa_schematic_V3.png|Version 1 Gradient Power Amplifier circuit providing a single channel of output current]

- Gradient Power Amplifier enclosure

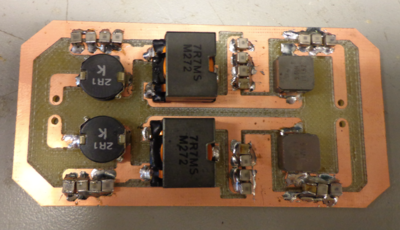

GPA boards mounted in enclosure with power supplies, terminal blocks, and digital-to-analog converter boards. The boards were run on bipolar +15V and -15V rails provided by CUI switching supplies. On-board regulators provide +12V, -12V, and +5V for powering the small ICs. The +12V fan is powered by a small JST connector on the CUI supplies.

Aluminum front panels were made using a water-jet cutter. Hammond NHC-14157 enclosures were used to house the GPAs and DACs. Click here for DXF file for front panel cut-outs. Note that Version 2 of the GPA board requires a horizontal slot for the RJ45 connectors instead of the vertical slot used here.

Version 2 of the GPA board

Version 2 of the board forthcoming....

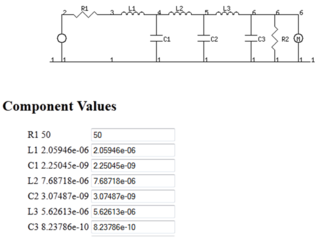

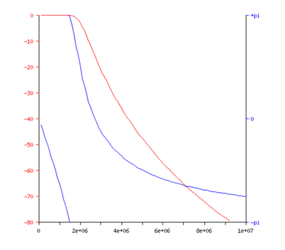

Gradient Filter

6th order butterworth low pass filters were added to the lines leading to the gradients.

The final version of these files can be downloaded as Eagle 5.11.0 and Gerber (for having the boards manufactured).

Note: Inductors were selected based on lead time and inductance and NOT on the package. Any inductor with similar inductance would work. The board was specifically designed for the following: 2.1 uH, 7.7 uH and 5.6 uH.

Note: All capacitor pads are for a 1206 package. There are four pads at each spot to allow for using multiple capacitors to obtain the specified value.